Welcome to our Steel Worlds Industries

E-mail us

steelworldsindustries2018@gmail.com

Aluminum sheets are made from pure aluminum or aluminum alloys. Common alloying elements include copper, magnesium, manganese, silicon, and zinc.

1000 Series: Pure aluminum (99% or higher), excellent corrosion resistance and high thermal/electrical conductivity.

3000 Series: Alloyed with manganese, known for good corrosion resistance and moderate strength.

5000 Series: Alloyed with magnesium, offers good corrosion resistance, especially in marine environments, and high strength.

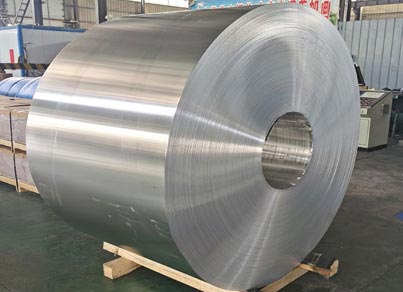

Aluminum coils are made from pure aluminum or aluminum alloys, often containing elements like magnesium, manganese, silicon, and zinc to enhance specific properties.

1000 Series: Nearly pure aluminum (99% or higher), offering excellent corrosion resistance and high thermal/electrical conductivity.

3000 Series: Alloyed with manganese, known for good corrosion resistance and moderate strength.

5000 Series: Alloyed with magnesium, providing good corrosion resistance, especially in marine environments, and high strength.

6000 Series: Alloyed with magnesium and silicon, offering balanced strength and workability with good corrosion resistance.

7000 Series: Alloyed with zinc, known for very high strength, commonly used in aerospace applications.

| Property | Details |

|---|---|

| Grades | 1100, 2024, 3003, 5052, 6061, 6063, 7075, 5083 |

| Material Type | Wrought Aluminum Alloys, Cast Aluminum Alloys |

| Standards | ASTM B209 (Plates & Sheets), ASTM B221 (Extruded Bars & Profiles), ASTM B241 (Pipes & Tubes), ISO 6361 |

| Chemical Composition | Primarily Aluminum (90-99%), with alloying elements like Copper, Manganese, Silicon, Magnesium, Zinc |

| Corrosion Resistance | Excellent corrosion resistance, particularly in grades like 5052, 5083, and 6061; some grades (e.g., 2024) are prone to corrosion without surface protection |

| Mechanical Properties | Tensile Strength: 110 - 570 MPa, Yield Strength: 45 - 505 MPa, depending on alloy and temper |

| Applications | Aerospace, Automotive, Construction, Marine, Electronics, Packaging, Transportation |

| Heat Treatment | Heat-treatable (e.g., 2024, 6061, 7075) and non-heat-treatable (e.g., 1100, 3003, 5052) alloys |

| Surface Finishes | Mill Finish, Anodized, Powder Coated, Polished, Brushed |

| Weldability | Good weldability in alloys like 5052 and 6061; others like 7075 are not easily weldable |

| Available Forms | Plates, Sheets, Bars, Pipes, Tubes, Extrusions, Foil |

| Advantages | Lightweight, excellent corrosion resistance, high strength-to-weight ratio, good formability, good conductivity |