Welcome to our Steel Worlds Industries

E-mail us

steelworldsindustries2018@gmail.com

Stainless Steel Seamless wire

Stainless steel seamless angle and wire are commonly used materials in various industries due to their strength, durability, and resistance to corrosion. Stainless steel seamless angle is a structural steel product that is shaped like an "L," with two legs forming a 90-degree angle. The term "seamless" means that the angle is made without any welds or joints, which enhances its strength and uniformity.

| Property | Details |

|---|---|

| Material Grades | 302, 304, 316, 321 |

| Diameter | 0.1mm to 10mm |

| Length | Coils or cut-to-length as specified |

| Surface Finish | Bright, matte, polished |

| Corrosion Resistance | High |

| Tensile Strength | 750 MPa to 2050 MPa (varies with grade and diameter) |

| Flexibility | Excellent |

| Applications | Medical, automotive, aerospace, industrial |

| Standards | ASTM A580/A580M, ASTM A313, EN 10270-3 |

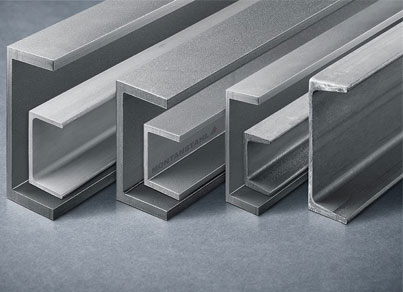

Monel Steel

Specifications: ASTM B164 / ASME B164

Dimensions: EN, DIN, JIS, ASTM, BS, ASME, AISI

Thickness: 3.0mm – 120mm

Length: 3MTR, 4MTR, 5MTR, 6MTR, or Custom Cut Sizes

Angle: 5mm to 9mm

Type: Angle, C Channel, U Channel, H Beam, I Beam, T Beam, W Beam, Chain

Channel: 40mm*20mm~300mm*300mm

Type: C Channel, U Channel

Duplex Steel Wire

Duplex steel wire, known for its unique combination of austenitic and ferritic stainless steel phases, offers high strength, excellent corrosion resistance, and good ductility. Duplex 2205 (UNS S32205): A commonly used grade with good overall performance in terms of strength and corrosion resistance. Duplex 2507 (UNS S32750): A super duplex grade offering higher strength and superior corrosion resistance, particularly in chloride-rich environments.

| Property | Details |

|---|---|

| Material Grades | Duplex 2205 (UNS S32205), Duplex 2507 (UNS S32750) |

| Diameter | 0.1mm to 10mm |

| Length | Coils or cut-to-length as specified |

| Surface Finish | Bright, matte, polished |

| Corrosion Resistance | High, especially in aggressive environments |

| Tensile Strength | 750 MPa to 1200 MPa (varies with grade and diameter) |

| Yield Strength | 450 MPa to 800 MPa (varies with grade and diameter) |

| Elongation | Typically 20% to 25% (varies with grade and diameter) |

| Applications | Marine, industrial, automotive, aerospace, chemical processing |

| Standards | ASTM A240, ASTM A276, EN 10088 |

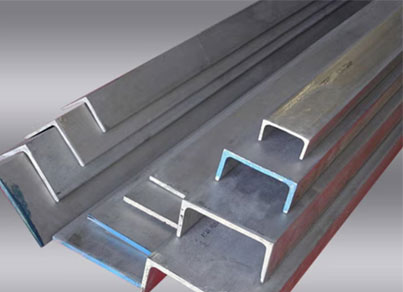

Hastelloy Steel

Specifications: ASTM B574 / ASME B574

Dimensions: EN, DIN, JIS, ASTM, BS, ASME, AISI

Thickness: 3.0mm – 120mm

Length: 3MTR, 4MTR, 5MTR, 6MTR, or Custom Cut Sizes

Angle: 5mm to 9mm

Type: Angle, C Channel, U Channel, H Beam, I Beam, T Beam, W Beam, Chain

Channel: 40mm*20mm~300mm*300mm

Type: C Channel, U Channel

Nickel & Nickel Alloy Wire

Nickel and its alloys are widely used in wire form for their excellent corrosion resistance, high temperature stability, and good mechanical properties. These wires are utilized in various industrial applications including electronics, aerospace, chemical processing, and marine environments. Performance: Reliable performance in demanding environments, including extreme temperatures and corrosive conditions.

| Property | Nickel Wire | Nickel Alloy Wire |

|---|---|---|

| Material Grades | Nickel 200, Nickel 201 | Nichrome, Monel, Invar, Hastelloy, Nitinol |

| Diameter | 0.025mm to 10mm | 0.025mm to 10mm |

| Purity | Up to 99.5% or higher | Varies by alloy composition |

| Corrosion Resistance | Excellent | Excellent, varies by specific alloy |

| Tensile Strength | 350 MPa to 600 MPa | 500 MPa to 1000 MPa, varies by alloy |

| Thermal Stability | High | High, varies by alloy |

| Electrical Conductivity | Good | Varies, generally good |

| Applications | Electronics, aerospace, chemical processing, medical | Aerospace, marine, chemical processing, medical, electronics |

| Standards | ASTM B160, ASTM B162 | ASTM B163, ASTM B164, ASTM B166, ASTM F2063 |

Titanium Steel

Specifications: ASTM B348 / ASME B348

Dimensions: EN, DIN, JIS, ASTM, BS, ASME, AISI

Thickness: 3.0mm – 120mm

Length: 3MTR, 4MTR, 5MTR, 6MTR, or Custom Cut Sizes

Angle: 5mm to 9mm

Type: Angle, C Channel, U Channel, H Beam, I Beam, T Beam, W Beam, Chain

Channel: 40mm*20mm~300mm*300mm

Type: C Channel, U Channel

Alloy Steel Wire

Alloy steel, which is steel combined with a variety of elements to improve its mechanical properties, is widely used in the form of angles and wires. These products are known for their enhanced strength, toughness, and resistance to wear and corrosion. Alloy steel angles are structural steel products with an "L" shape, made from alloy steels to provide superior mechanical properties compared to carbon steels. Alloy steel wire is a long, thin strand of alloy steel, often used for its enhanced mechanical properties.

| Property | Details |

|---|---|

| Material Grades | 4140, 4340, 6150, proprietary grades |

| Diameter | 0.1mm to 10mm |

| Length | Coils or cut-to-length as specified |

| Surface Finish | Bright, matte, polished, coated |

| Corrosion Resistance | Higher than plain carbon steel |

| Tensile Strength | 800 MPa to 1500 MPa (varies with grade and diameter) |

| Applications | Automotive, aerospace, industrial, construction |

| Standards | ASTM A29, ASTM A108, ASTM A510, proprietary specifications |

Copper Nickel Wire

Copper-nickel angles are structural products with an "L" shape, made from copper-nickel alloys to provide superior corrosion resistance and good mechanical strength. Copper-nickel wire is a continuous strand of copper-nickel alloy, known for its corrosion resistance and good electrical and thermal conductivity.

| Property | Details |

|---|---|

| Material Grades | CuNi 90/10 (UNS C70600), CuNi 70/30 (UNS C71500) |

| Diameter | 0.1mm to 10mm |

| Length | Coils or cut-to-length as specified |

| Surface Finish | Bright, matte, polished |

| Corrosion Resistance | Excellent in seawater and industrial environments |

| Electrical Conductivity | Good |

| Thermal Conductivity | High |

| Mechanical Strength | Good |

| Applications | Marine, electrical, industrial, automotive |

| Standards | ASTM B111, ASTM B466, ASTM B467, EN 12451 |