Welcome to our Steel Worlds Industries

E-mail us

steelworldsindustries2018@gmail.com

Key Features:

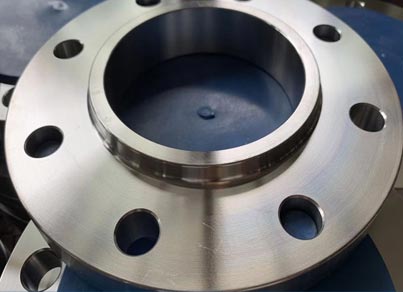

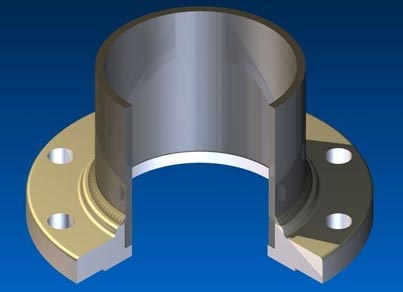

Socket Weld Connection: The pipe is inserted into a recess (or socket) in the flange and then welded around the joint. This creates a smooth, continuous connection that minimizes turbulence and pressure drop.

High Strength: Designed to handle high-pressure and high-temperature conditions due to the robust weld joint and the integral design.

Material Versatility: Available in various materials such as carbon steel, stainless steel, alloy steel, and high-strength alloys, suitable for different applications.

Common Types:

Standard Socket Weld Flange: The most common type, used in general applications where high strength and pressure resistance are required.

Socket Weld Flange with Raised Face: Features a raised face around the bolt holes to improve sealing and is used in higher pressure applications.

Socket Weld Flange with Flat Face: Includes a flat surface around the bolt holes, suitable for lower pressure applications.

Standards and Specifications:

ANSI/ASME B16.5: Standard for pipe flanges and flanged fittings, including socket weld flanges, specifying dimensions and tolerances.

ASTM A105: Specification for carbon steel forged fittings for piping applications.

ASTM A182: Standard for alloy and stainless steel pipe flanges, fittings, and valves.

ISO 9001: Quality management system standard ensuring consistent manufacturing and quality control.

| Property | Details |

|---|---|

| Function | Connects pipes, valves, and components by inserting the pipe into a recessed area and welding around the joint |

| Common Types | Standard Socket Weld Flange, Socket Weld Flange with Raised Face, Socket Weld Flange with Flat Face, Socket Weld Flange with Welded Neck |

| Materials | Carbon Steel, Stainless Steel, Alloy Steel, High-Strength Alloys |

| Pressure Ratings | Varies by material and design; typically up to 3000 PSI or more for metal flanges |

| Temperature Ratings | Depends on material; generally ranges from -50°F to 1500°F for metals |

| Connection Types | Socket weld connection with a smooth, continuous weld around the joint |

| Standards and Specifications | ANSI/ASME B16.5 (Flanges and Fittings), ASTM A105 (Carbon Steel), ASTM A182 (Alloy/SS), ISO 9001 (Quality) |

| Available Sizes | Typically from 1/2” to 24” diameter or larger |

| Surface Finishes | Bare, Galvanized, Epoxy Coated, Polyurethane Coated for corrosion protection |

| Applications | Oil and Gas, Chemical and Petrochemical, Power Generation, Water and Wastewater Treatment |

| Advantages | Strong and durable, leak-proof, smooth flow, versatile |