Welcome to our Steel Worlds Industries

E-mail us

steelworldsindustries2018@gmail.com

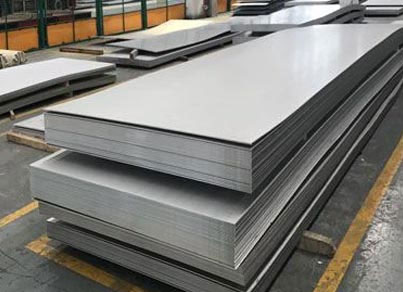

Stainless Steel Plates

Stainless steel plate are hot rolled and is very versatile and used in a variety of applications. It is primarily selected for its corrosion resistance, high tensile strength, temperature resistant, long lasting, easy formability & attractive appearance. Typical uses of stainless steel plate include for construction, food industry, breweries, infrastructure, vessels & tanks manufacturing, process industry, dairy, pharmaceutical, fabrication, etc. Stainless steel sheets, also commonly known as Cold Rolled Products, can be moulded into shapes for making tanks, vessels, fabrication, home décor, cookware etc.

| Standard | ASTM A240 |

| Grades | 304, 304L, 304H, 310, 310S, 316, 316L, 316Ti, 316LN, 317, 317L, 321, 347, 904L, SMO254. |

| Thickness | 0.5mm to 50mm |

| Sizes | 1250 x 2500, 1250 x 6000, 1500 x 3000, 1500 x 6000 & Custom cut sizes |

| Type | Coils, Sheets, Plates |

| Form | Cold Rolled, Hot Rolled |

Duplex & Super Duplex Plates

Duplex Steel plates contains high Chromium (18% - 28%) these plates are very high corrosion resistant, higher strength, excellent impact toughness at the same time its Nickel content is lower (5 - 6%). It is majorly used in chemical processing units, transportation, oil & gas exploration, pressure vessels, tanks, marine etc.

| Standard | ASTM A240 |

| Grades | UNS 31803, UNS 32205, UNS 32750, UNS 32760 |

| Thickness | 2mm to 25mm |

| Sizes | 1250 x 2500, 1250 x 6000, 1500 x 3000, 1500 x 6000 |

| Type | Coils, Sheets, Plates |

| Form | Cold Rolled, Hot Rolled |

Nickel & Nickel Alloy Plates

Nickel & Nickel Alloy Plates offer a range of advantages compared to other materials and are also highly priced. They are extremely strong and durable, meaning they can handle far more wear and tear than other metals, making them an ideal choice for many industrial applications. It has been used in a variety of industries over the years, including medical, automotive, marine engineering, chemical, petrochemical and construction. Its popularity is due to its strength & increased corrosion resistance.

| Standard | ASTM / ASME SB 162 |

| Grades | Nickel 200, Nickel 201, Monel 400, Monel K500, Inconel 625, Inconel 800, Inconel 825, Hastalloy C276, Alloy20 |

| Thickness | 1mm to 10mm |

| Sizes | 1250 x 2500, 1500 x 3000 |

| Type | Sheets, Plates |

Copper Plates

Copper plates has an excellent electric conductivity, high thermal conductivity, and good resistance to corrosion. It is used in variety of industry across the world marine, electrical parts, steam condensers, heat exchangers, boilers, tanks, cooling industry, chillers, military, architectural use & home décor.

| Grades | Oxygen free High Conductivity Copper, Electrolytic Tough Pitch , Phosphorous Deoxide Copper |

| Cold Rolled | 0.5mm – 25mm |

| Hot Rolled | 30mm – 100mm |

| Sizes | 1000 x 1000, 1000 x 2000, 1250 x 1250 x 1250 x 2500 |

Brass Plates

The composition of brass, generally 66% copper and 34% zinc, makes it a favourable substitute for copper as it exhibits greater resistance to corrosion and is more affordable. Brass is not as hard as bronze, and so is not suitable for most weapons and tools. Applications for brass plate includes construction equipment’s, ammunition, door locks, brackets, door plates, domestic interior fittings, electrical and plumbing components and architectural fascia's.

| Cold Rolled | 1.2mm – 16mm |

| Hot Rolled | 30mm – 75mm |

| Sizes | 1000 x 1000, 1250 x 1250 etc. |

Phosphorous Bronze Plates

Phosphorous Bronze is an alloy made with mixture of Copper & Tin as per the requirement. It has high yield strength, corrosion resistance and great hardness. It is primarily used in marine industry, manufacturing of shafts, gears, valve parts, electrical connectors and used for architectural purpose and is a premium priced metal.

| Size | 14" X 48" |

| Material Grade | PB1 |

| Thickness | 0.5mm to 12mm |

| Usage/Application | excellent corrosion resistance and ability to withstand high temperatures |

| Material | Phosphor Bronze |

Coil

Steel coils are used by various industries, as this type of metal is ideal for

building panels, walls, roof panels, power stations, ships, and various other

projects and construction undertakings. In addition to different sizes of steel

coils, there are also two different primary types: Cold-rolled steel coils.

Steel coil uses can vary depending on the industry, but some of its most popular

and widely-known applications include pipe-manufacturing, structural steel

members, electronic components, consumer goods, automotive parts, and many more.

Produced by passing steel through rollers at high temperatures (over 1700°F).

Produced by further processing hot rolled steel through cold reduction mills at room temperature.

Steel coils coated with a layer of zinc to prevent corrosion.

Made from stainless steel alloys, resistant to corrosion and staining.

Coils coated with a layer of paint or other coating materials.