Welcome to our Steel Worlds Industries

E-mail us

steelworldsindustries2018@gmail.com

Key Features:

Diameter Transition: Allows for the connection of pipes with different diameters without the need for a separate reducer, combining two functions in one component.

Material Versatility: Available in various materials such as carbon steel, stainless steel, alloy steel, and high-strength alloys, to accommodate different pressure, temperature, and environmental conditions.

Cost-Effective Design: By eliminating the need for additional fittings, reducing flanges provide a more cost-effective and space-saving solution for reducing pipe sizes.

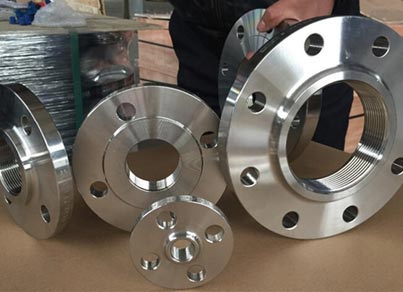

Common Types:

Reducing Weld Neck Flange: Designed with a tapered neck to accommodate welding to the pipe, providing a smooth transition between different pipe sizes and minimizing turbulence.

Reducing Slip-On Flange: The pipe slides through the center of the flange and is welded at the top and bottom for a secure connection, commonly used in lower-pressure systems.

Reducing Threaded Flange: Features internal threads for a screw-on connection, eliminating the need for welding in low-pressure applications.

Standards and Specifications:

ANSI/ASME B16.5: Standard for pipe flanges and flanged fittings, including reducing flanges, specifying dimensions and tolerances.

ANSI/ASME B16.47: Standard for large diameter steel flanges.

ASTM A105: Specification for carbon steel forged fittings for piping applications.

ASTM A182: Standard for alloy and stainless steel pipe flanges, fittings, and valves.

| Property | Details |

|---|---|

| Function | Connects pipes of different diameters without the need for separate reducers |

| Common Types | Reducing Weld Neck Flange, Reducing Slip-On Flange, Reducing Threaded Flange |

| Materials | Carbon Steel, Stainless Steel, Alloy Steel, High-Strength Alloys |

| Pressure Ratings | Varies by material and design; typically up to 1500 PSI or more |

| Temperature Ratings | Depends on material; generally ranges from -50°F to 1500°F for metals |

| Connection Types | Weld Neck, Slip-On, Threaded |

| Standards and Specifications | ANSI/ASME B16.5 (Pipe Flanges and Fittings), ANSI/ASME B16.47 (Large Diameter Steel Flanges), ASTM A105 (Carbon Steel), ASTM A182 (Alloy/SS), ISO 9001 (Quality) |

| Available Sizes | Typically from 1/2” to 60” diameter or larger depending on system requirements |

| Surface Finishes | Bare, Galvanized, Epoxy Coated, Polyurethane Coated for corrosion protection |

| Applications | Oil and Gas, Chemical Processing, Power Generation, Water and Wastewater Treatment |

| Advantages | Space-saving, cost-effective, easy installation, versatile applications |