Welcome to our Steel Worlds Industries

E-mail us

steelworldsindustries2018@gmail.com

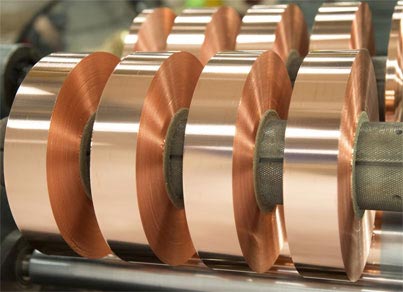

We offer enamelled copper wires and cables. Our vast range is available in different lengths and thicknesses and also as per the client's requirements. Having superior mechanical properties, these wires very well meet with all the requirement of the clients. Our wires and cables have excellent tensile strength and can easily resist high temperature and other adverse conditions.

With the support of a team, we manufacture a premium grade of Copper Coated Stitching Wire & Galvansied Stitching Wire. We can provide our range as per the requirement of customers. Our range is available in the following sizes: Flat Gauges: 12X25, 12X22, 13 X 25, 14 X 25 & 17X25 Round Gauges: 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28 NARROW FLAT: 21X23, 21X24, 21X25, 20X22, 20X23, 20X24, 19X22, and 19X25

| Property | Details |

|---|---|

| Grades | C110 (Electrolytic Tough Pitch - ETP Copper), C101 (Oxygen-Free Copper), C172 (Beryllium Copper), C71500 (Copper-Nickel), C23000 (Red Brass), C28000 (Muntz Metal) |

| Material Type | Pure Copper, Copper Alloys |

| Standards | ASTM B152 (Copper Sheets & Plates), ASTM B187 (Copper Bars), ASTM B88 (Pipes), ASTM B75 (Tubes), ASTM B111 (Seamless Tubes for Heat Exchangers), ASTM B194 (Beryllium Copper) |

| Chemical Composition | Primarily Copper (99% in pure grades), with alloying elements such as Zinc, Tin, Nickel, Beryllium in copper alloys |

| Corrosion Resistance | Excellent corrosion resistance, especially in marine, atmospheric, and chemical environments; specific alloys offer improved resistance to stress corrosion cracking |

| Mechanical Properties | Tensile Strength: 200 - 1100 MPa, Yield Strength: 70 - 1000 MPa, depending on alloy and temper |

| Electrical Conductivity | High electrical conductivity, especially in pure copper grades like C110 and C101 (IACS ~100%) |

| Applications | Electrical Wiring, Plumbing, Heat Exchangers, Electronics, Architectural, Marine, Coinage, Industrial Valves |

| Heat Resistance | Good heat resistance, with excellent thermal conductivity, especially in pure copper grades |

| Surface Finishes | Mill Finish, Polished, Electroplated, Tin Coated, Silver Plated, Oxide Coated |

| Weldability | Excellent weldability, particularly in pure copper and some alloys; requires careful control of oxygen levels in some cases (e.g., oxygen-free copper) |

| Available Forms | Plates, Sheets, Bars, Pipes, Tubes, Wires, Forgings |

| Advantages | High electrical and thermal conductivity, excellent corrosion resistance, good ductility and formability, antimicrobial properties |